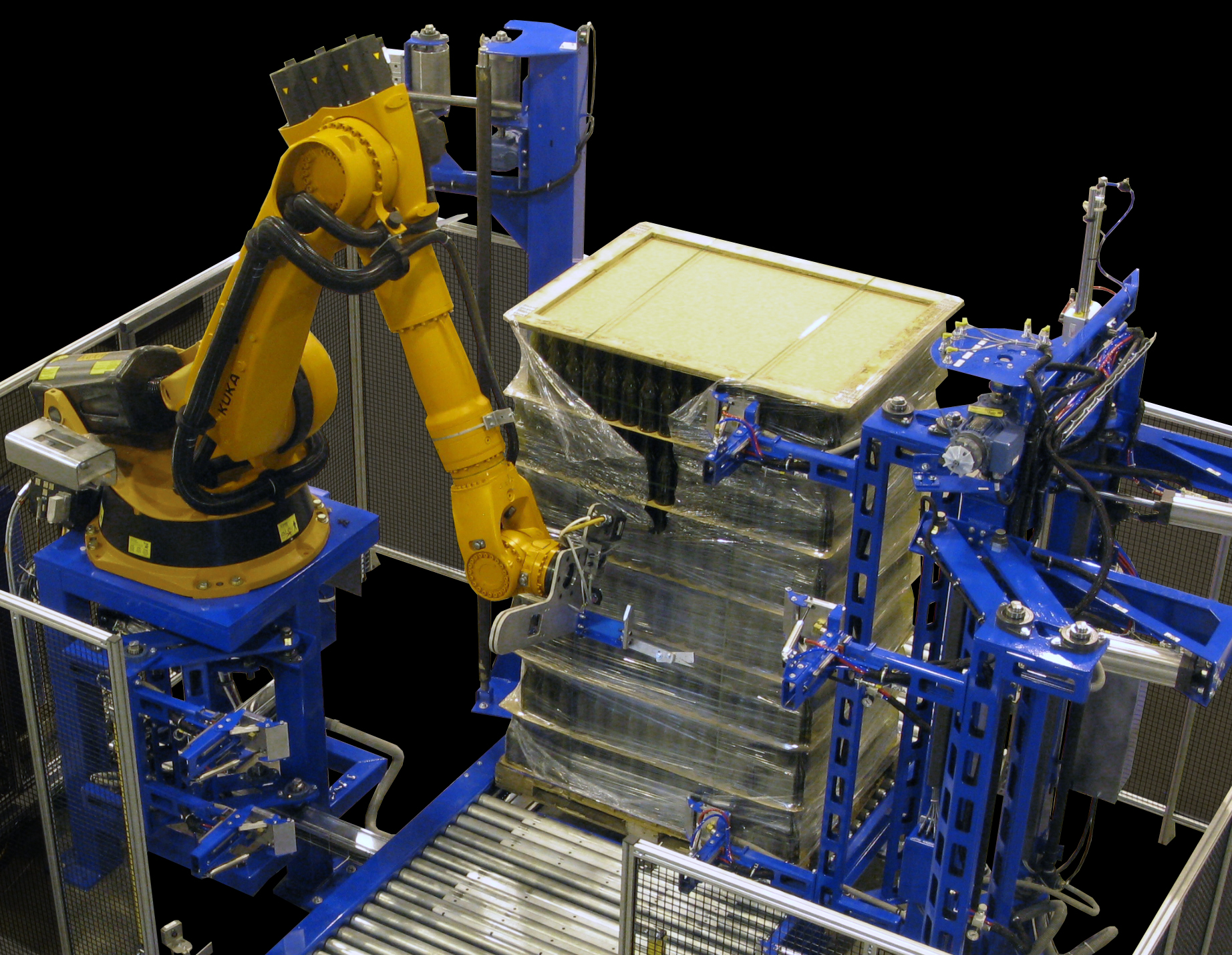

ROMEOVILLE, Ill. — June 6, 2016 — BW Container Systems, a division of Barry Wehmiller, recently placed its 250th robot in the Global packaging market. With installations in 13 countries, the company has provided solutions for diverse markets on four continents. From soft drink, brewery, pet care, and frozen food to wineries, distilleries and can manufacturers, BW Container Systems is one of the world’s largest suppliers of robotic solutions to the packaging industry. The company has largely focused its robotic automation efforts on products such as case and bulk palletizing and depalletizing, destrapping, pallet unwrapping and can end automation.

“The robotics industry is seeing great growth right now, especially in sectors such as automotive and general industry. The execution of 250 robotic systems in such a short period of time is a significant accomplishment for any company, but it is especially significant for a North American packaging company,” said Jim Cooper, vice president of sales and marketing for KUKA Robotics. “The fact that BW Container Systems has been able to grow and sustain this business shows the commitment that the organization has to robotic solutions within their product portfolio and shows the innovation that BW Container Systems is providing to the market.”

“We are very proud of our robotics initiative. I think that our success is a combination of technology and people, but it all starts with our people,” said Pete Carlson, president of BW Container Systems. “The addition of robotic automation to our product portfolio has been exciting for our clients and energizing for our team. Our investment in robotics allows us to continue to bring innovative solutions to our clients and it enables our clients to have the flexibility to run the variety of products that they need to run with high operational efficiency.”

BW Container Systems has placed packaging systems in China, Mexico, Poland, Peru and Belgium. While it offers a variety of standard proven solutions, it continues to create innovative solutions. The company’s rotary palletizer was specifically designed for clients who seek to feed a single palletizer from multiple packaging lines and has been popular in industries such as paperboard manufacturing and frozen seafood. The company’s destrapping and unwrapping technology is applicable for virtually any bulk container manufacturing operation in the world.